| Type | Measure |

|---|---|

| EN AW-Al Mg Si 0.5 | Material Designation DIN EN 573 |

| Tensile strength RM | min. 245 N/mm² |

| Yield Point Rp 0.2 | min. 195 N/mm² |

| Ductile yield A5 | min. 10% |

| Ductile yield A10 | min. 8% |

| Moulus of elasticity E | 70.000 N/mm² |

| Hardness HB | approx. 75 Brinell hardness |

| Coefficient of Linear expansion | 23.4 x 10⁻⁶ 1/K |

| Tolerances | DIN EN 12020-2 |

| Anodizing Process | clear E6C0, black E6C35 |

| Minimum Thickness of anodizing layer | approx. 10-15 μm |

Aluminum Profile Technical Data

Framing the Future

General Information

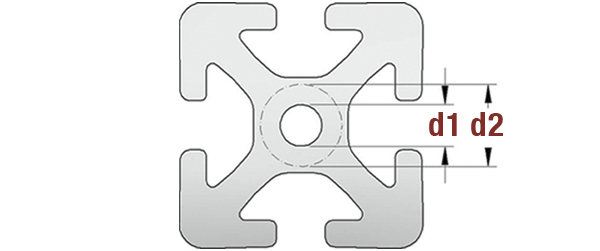

Core Bores

| Groove Style | Drilled Hole d1 | Reboreable up to d2 | ||

|---|---|---|---|---|

| Metric | Standard | Metric | Standard | |

| Ø 4.3mm ±0.1mm for M5 | [Ø.17″ ± .004″ for UNC 10-24] | Ø 6.0mm or M6 | [Ø.23″ or UNC 1/4″-20] | |

| Ø 5.0mm ±0.2mm for M6 | [Ø.20″ ± .008″ for UNC 1/4″-20] | Ø 8.0mm or M8 | [Ø.31″ or UNC 3/8″-16] | |

| Ø 6.8mm ±0.2mm for M8 | [Ø.26″ ± .008″ for UNC 5/16″-18] | Ø 13.0mm or M12 (not Eco.) | [Ø.51″ or UNC 9/16″-12] (not Eco.) | |

Tensile Loading Capacity

| Groove Style | Profile | T-Slot Nut | Heavy-Duty T-Slot Nut |

|---|---|---|---|

| L5 | 1,000N | N/A | |

| L6 Standard | 3,500N | N/A | |

| L6 Light | 1,000N | N/A | |

| L8 Standard | 10,000N | 15,000N | |

| L8 Light | 5,000N | 7,000N | |

| L8 Economy | 3,500N | 6,000N |

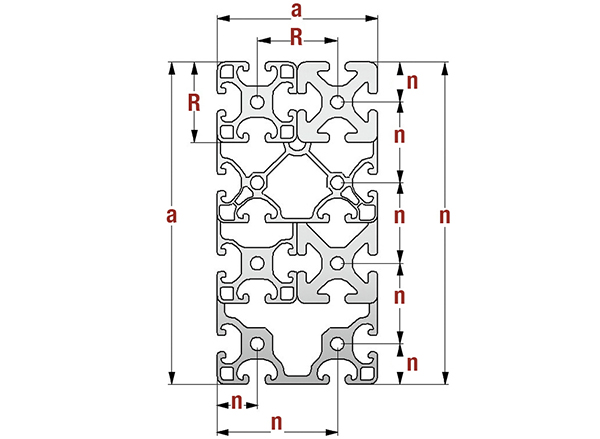

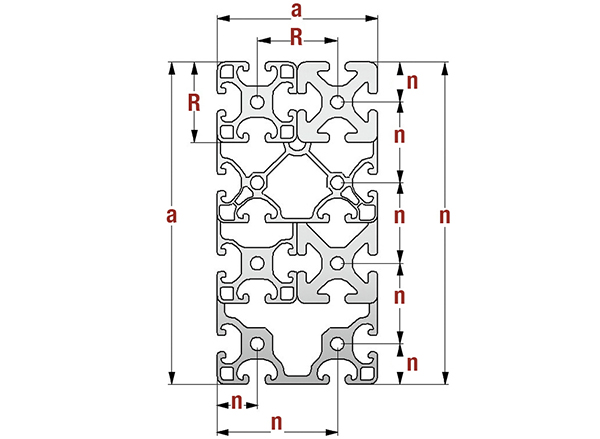

External Dimensions & T-slot Positions

| Modular Dimension R | |||

|---|---|---|---|

| Profile Edge length a mm [in] | External Groove Position and dimension n ± mm [in] | ||

|---|---|---|---|

| Range | Tolerance | ||

| Metric | Standard | Metric | Standard |

| 0 – 10 | [.40″] | ±0.1 | ±0[.004″] |

| 10 – 20 | [0.40″] – [.78″] | ±0.15 | ±[.006″] |

| 20 – 40 | [.78″] – [1.57″] | ±0.2 | ±[.008″] |

| 40 – 60 | [1.57″] – [2.36″] | ±0.3 | ±[.011″] |

| 60 – 80 | [2.36″] – [3.15″] | ±0.4 | ±[.015″] |

| 80 – 100 | [3.15″] – [3.93″] | ±0.45 | ±[.018″] |

| 100 – 120 | [3.93″] – [4.72″] | ±0.5 | ±[.020″] |

| 120 – 160 | [4.72″] – [6.30″] | ±0.6 | ±[.023″] |

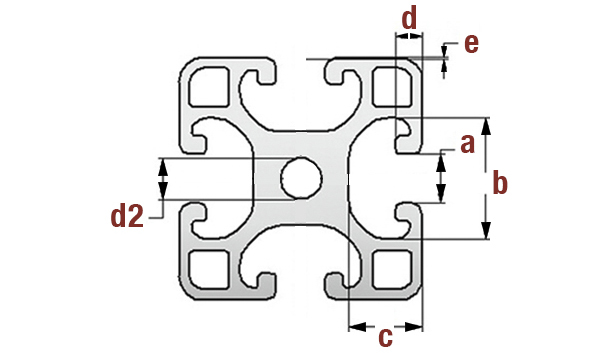

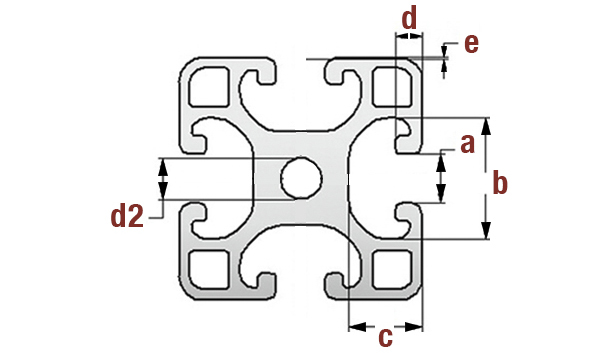

Groove Dimensions

| Area | 5 | 6 | 8 | |||

|---|---|---|---|---|---|---|

| Metric | Standard | Metric | Standard | Metric | Standard | |

| a | 5.0mm +0.3/-0 | [.19″] +0.011/-0 | 6.2mm +0.3/-0 | [.24″] +0.011/-0 | 8.0mm +0.4/-0 | [.31″] +0.015/-0 |

| b | 11.5mm +0.3/-0 | [.45″] +0.011/-0 | 16.3mm +0.3/-0 | [.64″] +0.011/-0 | 20.0mm +0.4/-0 | [.78″] +0.011/-0 |

| c | 6.35mm ±0.15 | [.25″] ±0.006 | 9.75mm +0.2/-0 | [.38″] +0.008/-0 | 12.25mm +0.3/-0 | [.48″] +0.011/-0 |

| d | 1.8mm ±0.1 | [.07″] ±0.004 | 3mm +0/-0.25 | [.11″] +0/-0.01 | 4.5mm +0.3/-0 | [.17″] +0.011/-0 |

| e | 0.15mm ±0.1 | [.17″] ±0.004 | 0.15mm ±0.1 | [.17″] ±0.004 | 0.2mm ±0.1 | [.17″] ±0.004 |

| d1 | 4.3mm ±0.1 | [.17″] ±0.004 | 5.0mm +0.2/-0 | [.17″] +0.008/-0 | 6.8mm +0.2/-0 | 6[.17″] +0.008/-0 |

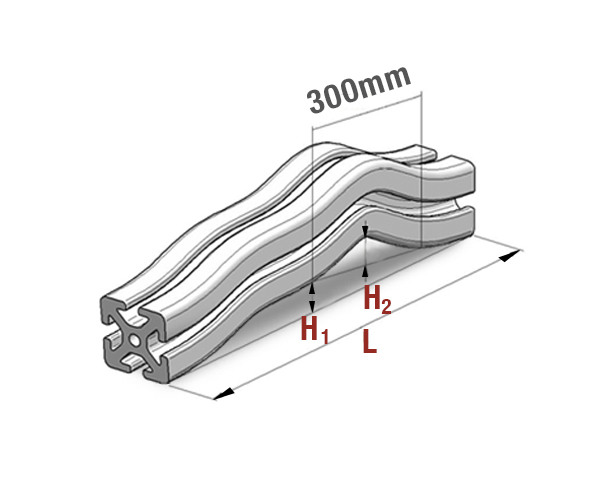

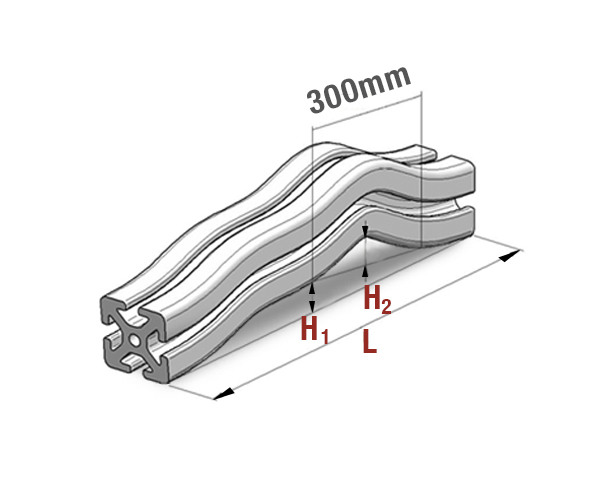

Straight Tolerance Longitudinal

| Length L – up to | Straightness tolerance H1 for nominal length L | ||

|---|---|---|---|

| Metric | Standard | Metric | Standard |

| 1000mm | [39.37″] | 0.7mm | [0.03″] |

| 2000mm | [78.74″] | 1.3mm | [0.05″] |

| 3000mm | [118.11″] | 1.8mm | [0.07″] |

| 4000mm | [157.48″] | 2.2mm | [0.09″] |

| 5000mm | [196.85″] | 2.8mm | [0.11″] |

| 6000mm | [236.22″] | 3.0mm | [0.12″] |

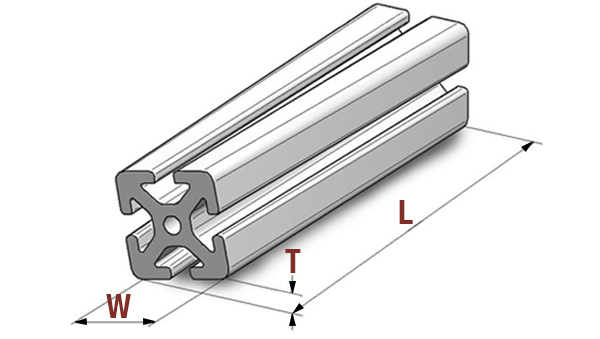

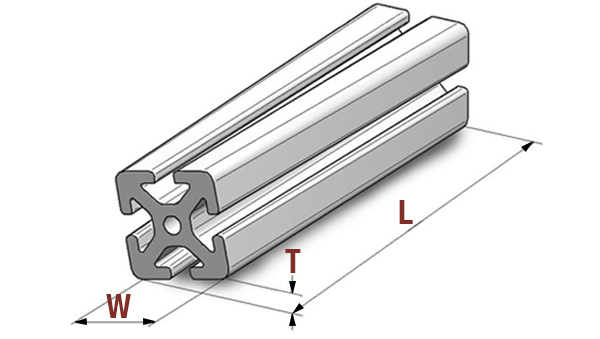

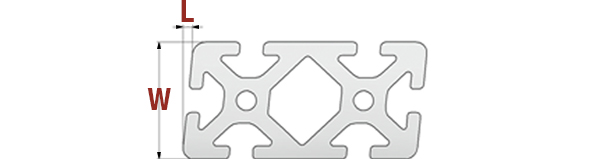

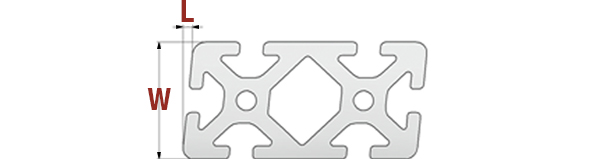

Torsion

| width W in mm | Torsion tolerance T mm [inch] for length L mm [inch] | ||||||

|---|---|---|---|---|---|---|---|

| from | to | up to 1000mm [39.37″] | up to 2000mm [78.74″] | up to 3000mm [118.11″] | up to 4000mm [157.48″] | up to 5000mm [196.85″] | up to 6000mm [236.22″] |

| – | 25 | 1.0[0.04″] | 1.5[0.06″] | 1.5[0.06″] | 2.0[0.08″] | 2.0[0.08″] | 2.0[0.08″] |

| 25 | 50 | 1.0[0.04″] | 1.2[0.05″] | 1.5[0.06″] | 1.8[0.07″] | 2.0[0.08″] | 2.0[0.08″] |

| 50 | 75 | 1.0[0.04″] | 1.2[0.05″] | 1.2[0.05″] | 1.5[0.06″] | 2.0[0.08″] | 2.0[0.08″] |

| 75 | 100 | 1.0[0.04″] | 1.5[0.06″] | 1.8[0.07″] | 2.2[0.09″] | 2.5[0.10″] | 3.0[0.12″] |

| 100 | 125 | 1.2[0.05″] | 1.5[0.06″] | 1.8[0.07″] | 2.2[0.09″] | 2.5[0.10″] | 3.0[0.12″] |

| 125 | 150 | 1.2[0.05″] | 1.5[0.06″] | 1.8[0.07″] | 2.2[0.09″] | 2.5[0.10″] | 3.0[0.12″] |

| 150 | 200 | 1.5[0.06″] | 1.8[0.07″] | 2.2[0.09″] | 2.6[0.10″] | 3.0[0.12″] | 3.5[0.14″] |

| 200 | 300 | 1.8[0.07″] | 2.5[0.10″] | 3.0[0.12″] | 3.5[0.14″] | 4.0[0.16″] | 4.5[0.18″] |

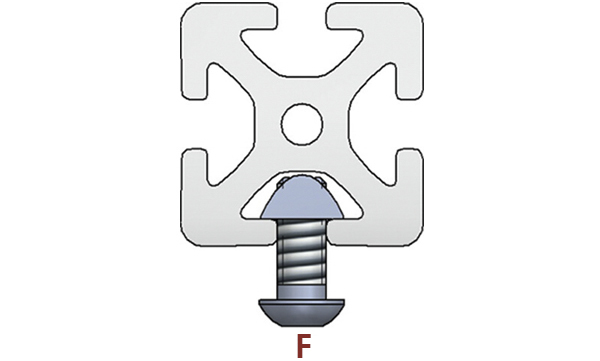

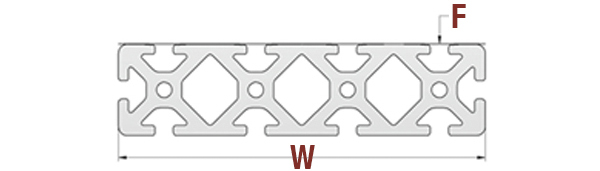

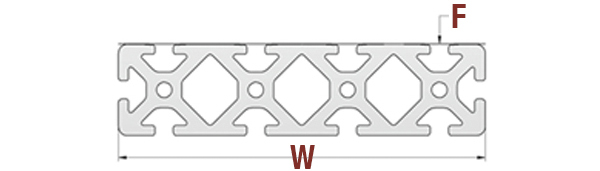

Straight Tolerance Transverse

| width W in mm | straightness tolerance F | ||

|---|---|---|---|

| from | to | mm | inches |

| 0 | 30 | 0.2 | 0.008″ |

| 30 | 60 | 0.3 | 0.012″ |

| 60 | 100 | 0.4 | 0.016″ |

| 100 | 150 | 0.5 | 0.019″ |

| 150 | 200 | 0.7 | 0.027″ |

| 200 | 250 | 0.85 | 0.033″ |

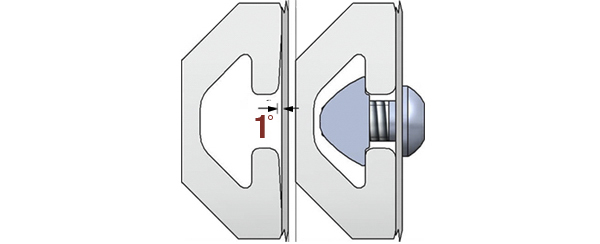

Angle Tolerance

| width W in mm | Angular Tolerance L ± | ||

|---|---|---|---|

| from | to | mm | inches |

| 0 | 20 | 0.2 | 0.008″ |

| 20 | 40 | 0.4 | 0.016″ |

| 40 | 60 | 0.6 | 0.023″ |

| 60 | 80 | 0.8 | 0.031″ |

| 80 | 120 | 1.2 | 0.047″ |

| 120 | 200 | 1.5 | 0.059″ |